Top True Union Ball Valve Manufacturer in China - Quality Guaranteed

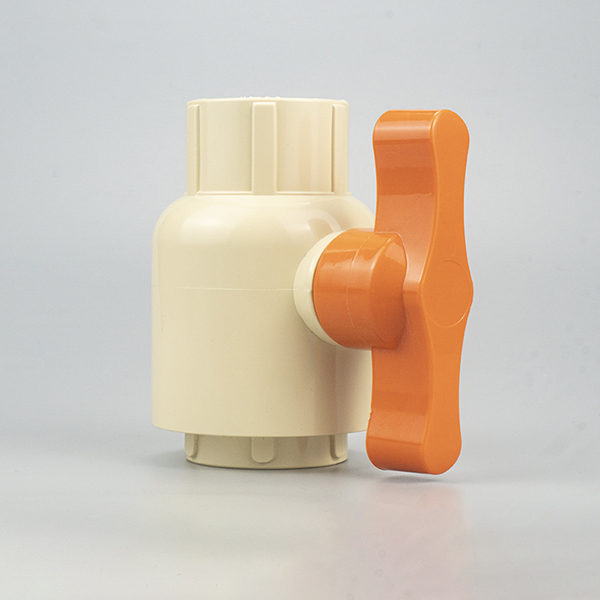

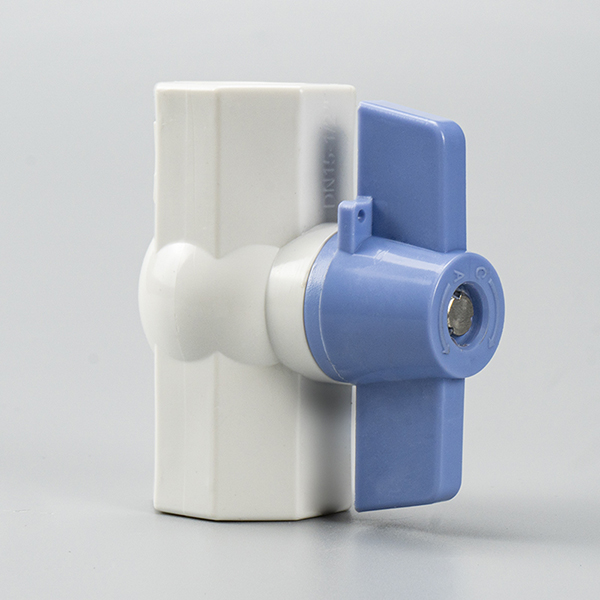

As a leading True Union Ball Valve Manufacturer based in China, I offer high-quality products designed to meet the diverse needs of industries worldwide. Our True Union Ball Valves are engineered for exceptional durability and performance, making them ideal for various applications. I understand that B2B purchasers like you seek reliable and efficient solutions, which is why our valves come with features such as easy installation and maintenance. Not only do our products ensure optimal flow control, but they also provide long-lasting service, minimizing downtime for your operations. With years of experience in the industry, I am committed to delivering top-tier manufacturing standards and personalized service to support your business requirements. Collaborate with me to enhance your operations and achieve seamless performance with our True Union Ball Valves, tailored specifically for your needs.

True Union Ball Valve Manufacturer Now Trending Guarantees Peak Performance

In the dynamic world of industrial components, the demand for reliable and efficient ball valves is on the rise. True union ball valves are essential for maintaining peak performance across various applications, including water treatment, chemical processing, and petroleum industries. Distinguished by their unique design, these valves combine durability with user-friendly features, making them increasingly popular among global procurement professionals. Today’s market demands innovation and quality, and sourcing manufacturers that prioritize these elements is crucial. When selecting a true union ball valve, it's important to consider factors such as material selection, ease of maintenance, and adaptability to different systems. Leading manufacturers are now integrating advanced technologies to enhance the functionality and longevity of their products, ensuring that clients receive solutions that exceed expectations and stand the test of time. As global industries continue to evolve towards more sustainable and efficient practices, investing in high-quality ball valves is a strategic move for companies aiming to enhance operational efficiency. Suppliers that offer exceptional products along with robust performance guarantees are well-positioned to meet the growing needs of industries worldwide. With this innovation-driven approach, businesses can secure a competitive edge in an ever-changing market landscape.

True Union Ball Valve Manufacturer Now Trending Guarantees Peak Performance

| Feature | Specification | Material | Size Range | Applications |

|---|---|---|---|---|

| Pressure Rating | Up to 600 PSI | PVDF, PVC, CPVC | 1/2" to 12" | Chemical processing, Water treatment |

| Temperature Range | -20°F to 200°F | Stainless Steel, Brass | 3/4" to 10" | Oil and gas, HVAC systems |

| Actuation Type | Manual and Automated | Forged Steel, Alloy | 1" to 8" | Pharmaceuticals, Food processing |

| End Connection | Socket, Threaded, Flanged | Ductile Iron, Nylon | 1/2" to 16" | Mining, Pulp and paper |

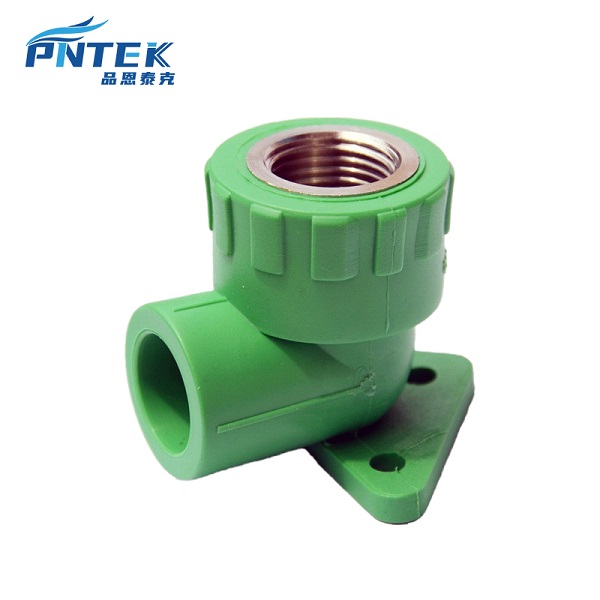

Related Products