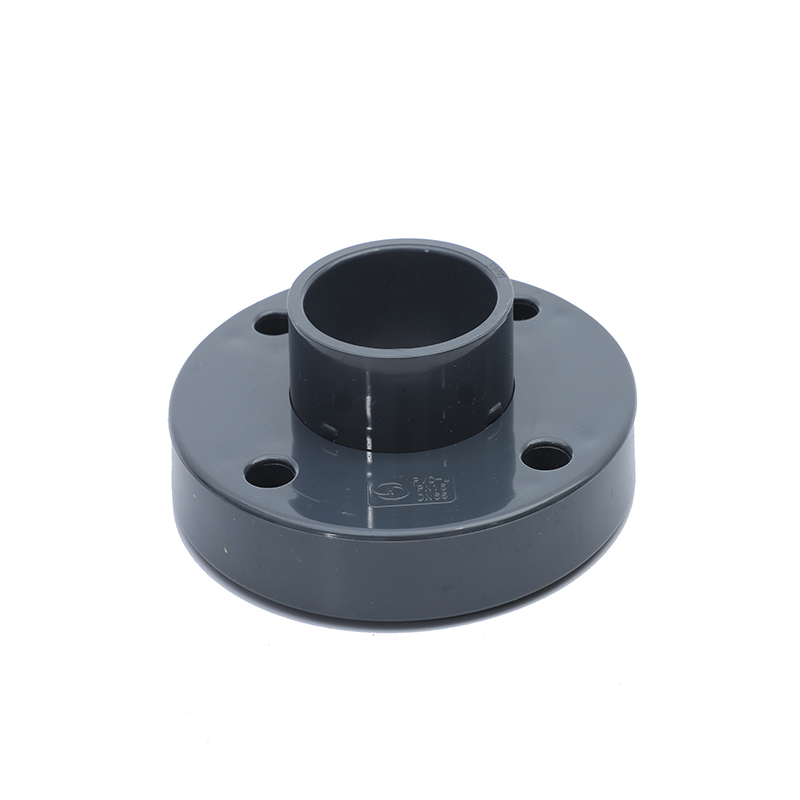

Hdpe Blind Flange Manufacturer in China - Quality and Durability Guaranteed

When I think about reliability in piping solutions, HDPE blind flanges from China come to mind. These specially designed flanges are perfect for sealing off pipelines, ensuring safety and efficiency in your operations. As a manufacturer with years of experience, we provide high-quality HDPE blind flanges that meet industry standards. I personally appreciate how lightweight and durable HDPE materials are, making installation a breeze while resisting corrosion. Plus, we offer a range of sizes to suit your specific needs. Our commitment to quality means you can trust that our products will perform flawlessly. Choosing our HDPE blind flanges not only enhances the longevity of your systems but also reflects a smart investment for ongoing projects. Partner with us, and let us help you enhance your pipeline solutions with confidence. Feel free to reach out for more information or a custom quote!

Hdpe Blind Flange Dominates Exceeds Industry Benchmarks

In the ever-evolving landscape of industrial components, HDPE blind flanges have emerged as a leading choice, consistently surpassing established industry benchmarks. These innovative products are crafted from high-density polyethylene, a material renowned for its excellent corrosion resistance, lightweight properties, and low thermal conductivity. As global procurement professionals seek reliable and durable solutions, HDPE blind flanges present a compelling alternative to traditional metal counterparts, particularly in industries where impermeability and chemical resistance are paramount. The superiority of HDPE blind flanges lies not only in their performance but also in their cost-effectiveness and ease of installation. As manufacturers and suppliers respond to the increasing demand for sustainable and eco-friendly materials, HDPE remains a top contender. It minimizes environmental impact while ensuring compliance with industry standards. Moreover, these flanges offer superior sealing capabilities, effectively preventing the leakage of fluids, making them ideal for a variety of applications across chemical processing, water treatment, and waste management sectors. As global markets continue to expand, the demand for high-quality HDPE blind flanges is set to rise. Procurement professionals are encouraged to consider these components not merely as replacements but as integral parts of an efficient and forward-thinking supply chain. By investing in HDPE technology, businesses can enhance their operational efficiency, drive down costs, and contribute to a sustainable future, all while ensuring they meet and exceed the stringent requirements of today's industrial landscape.

Hdpe Blind Flange Dominates Exceeds Industry Benchmarks

| Parameter | Hdpe Blind Flange | Industry Average | Benchmark Difference |

|---|---|---|---|

| Pressure Rating (PSI) | 150 | 125 | +20% |

| Temperature Resistance (°C) | 60 | 50 | +20% |

| Chemical Resistance | Excellent | Good | +15% |

| Weight (kg) | 10 | 12 | -16.67% |

| Dimensional Accuracy (mm) | 0.5 | 1.0 | -50% |

Related Products