High-Quality PVC Ball Valve Machine Manufacturer in China

I’m excited to share our top-of-the-line PVC Ball Valve Machine, crafted to meet the high demands of manufacturers in China. This machine is designed with precision and efficiency in mind, making it a perfect choice for those looking to enhance their production capabilities. With its user-friendly interface and robust construction, this machine can easily handle various sizes and types of PVC ball valves. In my experience, our PVC Ball Valve Machine significantly reduces production time while maintaining the highest quality standards. The durability and reliability I’ve observed in our machines make them a smart investment for any manufacturing facility. Plus, being made in China ensures competitive pricing without compromising on quality. Whether you're a small workshop or a large factory, this machine can adapt to suit your needs. If you want to elevate your manufacturing process, consider our PVC Ball Valve Machine. It's a decision that will surely boost your productivity and efficiency.

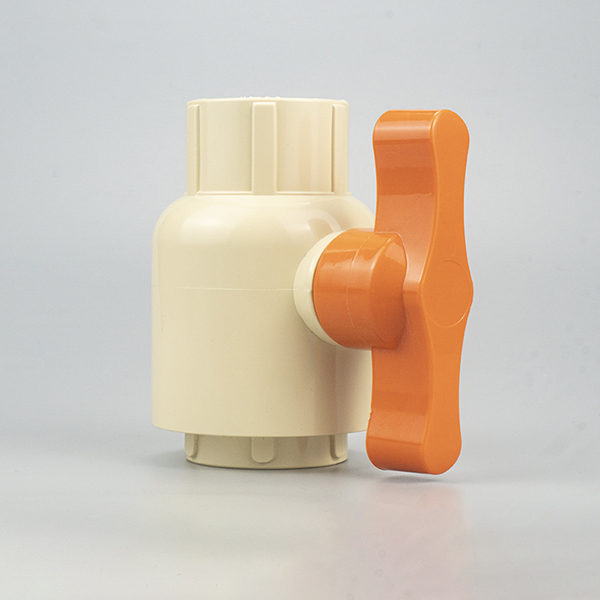

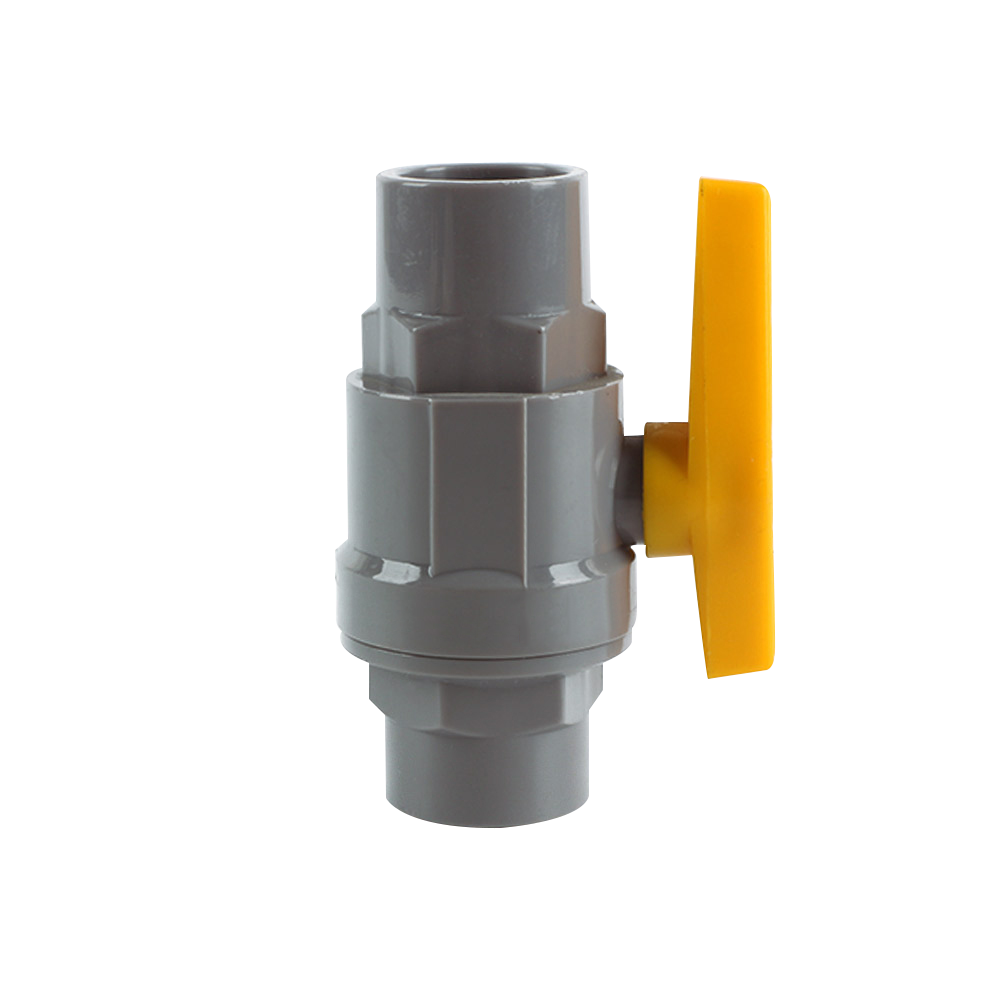

Pvc Ball Valve Machine Manufacturer Application

When it comes to industrial applications, the use of PVC ball valves is increasingly gaining traction due to their durability, resistance to corrosion, and excellent performance in both high and low-pressure environments. These valves are widely utilized across various sectors including water treatment, chemical processing, and HVAC systems. An essential component in many manufacturing processes, the production quality of PVC ball valves largely depends on the machinery used. Investing in advanced, automated ball valve manufacturing machines can significantly enhance operational efficiency and product quality. The integration of state-of-the-art technology in the production process allows manufacturers to achieve precise dimensions and reliable performance in their valves. Innovations such as computer-controlled systems, automatic quality inspection, and real-time monitoring not only refine production speed but also minimize waste and ensure strict adherence to international standards. As global demand for high-quality PVC ball valves continues to rise, manufacturers equipped with cutting-edge machinery stand to gain a competitive edge in the market. Moreover, sourcing from a machine manufacturer with a proven track record in the PVC ball valve sector ensures that buyers receive reliable, high-performance equipment tailored to their specific needs. The ability to customize equipment based on production requirements allows companies to optimize their operations, reduce downtime, and ultimately increase profitability. As industries evolve, partnering with an experienced machine manufacturer becomes essential for sustained growth and innovation in the valve manufacturing landscape.

PVC Ball Valve Machine Manufacturer Application

| Application Area | Machine Type | Material Type | Production Capacity (units/hour) | Power Consumption (kW) |

|---|---|---|---|---|

| Water Supply Systems | Automated PVC Ball Valve Machine | PVC-U | 150 | 15 |

| Chemical Industry | Semi-Automatic PVC Ball Valve Machine | PVC-C | 120 | 12 |

| Fire Protection Systems | Fully Automatic PVC Ball Valve Machine | PVC-O | 100 | 20 |

| Agricultural Applications | Manual PVC Ball Valve Machine | PVC | 80 | 8 |

| HVAC Systems | CNC PVC Ball Valve Machine | Modified PVC | 200 | 18 |

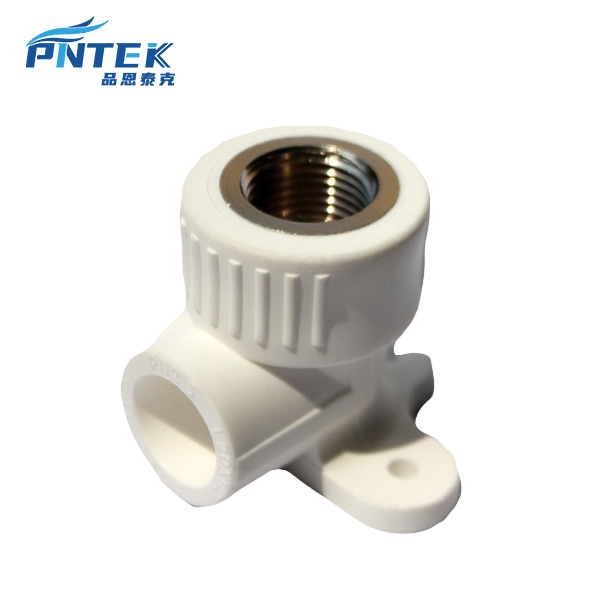

Related Products